TIME:2025-06-02

BROWSE:

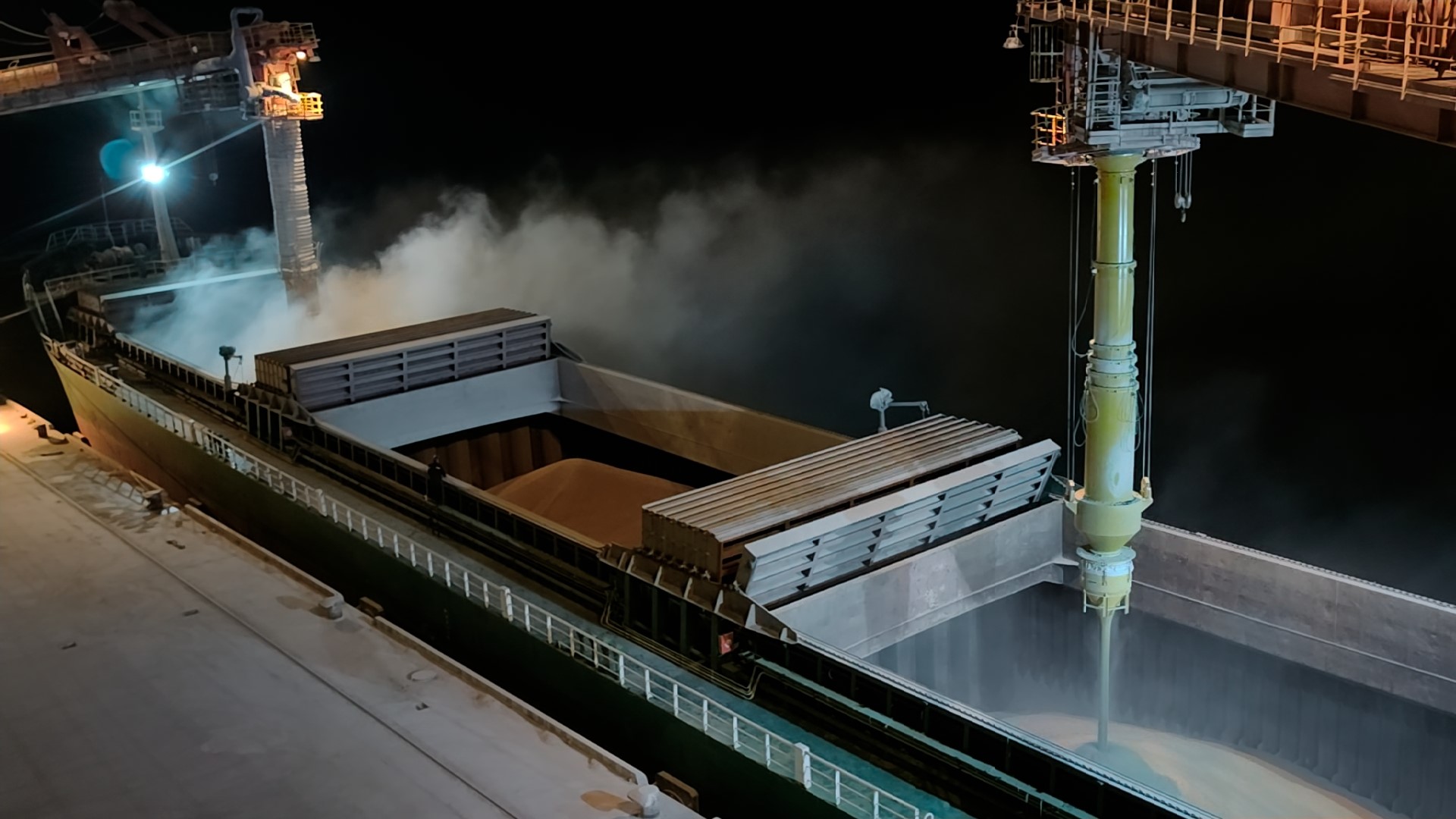

Fragmentation-resistant Powerless Dust Suppression Telescopic Chute

Technical Principle

A specialized integrated conveying system designed for bulk materials (e.g., coal, ores, grains) in high-throughput, large-drop-height loading/unloading scenarios. Its core components include:

①Powerless Dust Suppression Deflector Hood (optional) at conveyor head

②Straight-tube Fragmentation-resistant Telescopic Chute

③Multi-functional Buffer Chamber

④Wide-flow Powerless Dust Suppression Hopper

⑤Automatic Material Level Detection & Blockage Relief System

Through alternating inverted V-shaped buffer plates and flat buffer plates, combined with breathable flexible sealing rings, shock-absorbing materials, and powerless dust suppression technology, the system achieves multi-stage balanced material deceleration and full-process dust control. Widely applicable to high-intensity industrial environments such as ports, mines, and cement plants, offering integrated advantages of efficiency, environmental compliance, and low maintenance.

This system incorporates multiple proprietary technologies, including:

①Breathable flexible sealing material dust suppression technology;

②Multi-stage anti-fragmentation composite technology;

③Wide-flow powerless dust suppression technology;

④Conveyor head deflector powerless dust suppression technology;

⑤Chute hoisting and tube connection technology;

⑥Material level monitoring & early warning;

⑦Automatic blockage relief system;

⑧Triple-interlock technology for conveyor belt control systems.

Product Features

①High Throughput Capacity: Maximum flow capacity up to 3,000 m³/h.

②Large Drop Height: Telescopic extension length exceeds 30 meters.

③Wide Flow Range: With integrated Powerless Dust Suppression Hopper,

stable operation within median output (1±30%) while effectively containing dust dispersion.

④High Dust Suppression Efficiency: Over 80% dust containment rate.

⑤Energy Efficiency: Eliminates reliance on negative pressure dust

collection systems or requires minimal negative pressure (micro-negative pressure).

⑥Material Loss Reduction: Decreases material waste by over 80%.

⑦Low Maintenance: Removes traditional dust covers with virtually no

wearable components.

⑧Low Breakage Rate: Multi-stage deceleration and shock-absorbing

materials control material flow dynamics, reducing fragmentation by 50%+.

⑨Heavy-duty Construction: High vertical/circular rigidity supports

auxiliary equipment installation (e.g., material trajectory monitoring).

⑩Dynamic Load Reduction: Buffer mechanisms with spring dampers and

shock-absorbing materials disperse kinetic energy, significantly lowering peak dynamic loads.

Applicable Materials

①Bulk Materials: Coal, ores, grains, cement raw materials, fertilizers, etc.

②Powdered Materials: Pulverized coal, mineral powders, grain dust, fly ash, etc.

③Granular Materials: Aggregates, pellets, seeds, industrial granules, etc.

Chinese

Chinese