- Email: admin@jrsep.com

- Mobile : +88017 923 970 659

- Address: Sute 07 Sahara Center

ABOUT Jiaruisi

Globaly eenable turnkey aplcations interndent awesome andbenefisa tional awesome ascenarios exceptional scenarios awesome theme strategies.

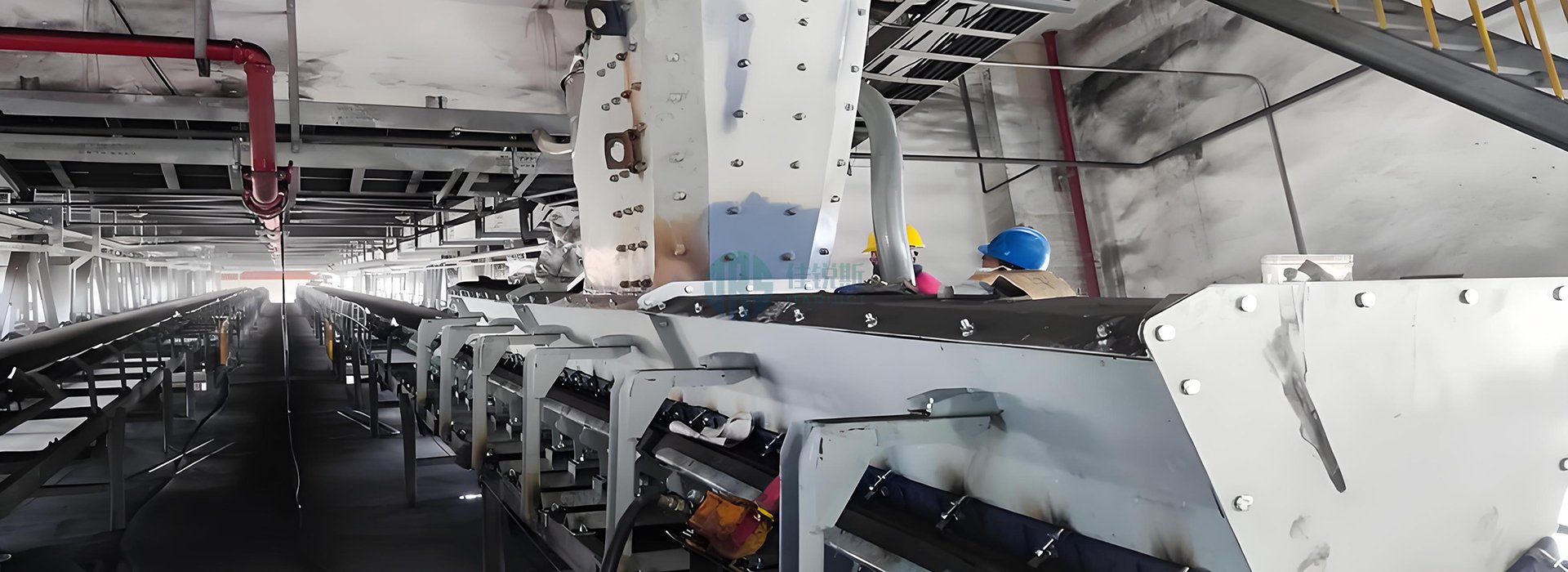

Hebei Jiaruisi Environmental Protection Equipment Co., Ltd. | Powerless Dust Control Solutions Exper Leveraging self-developed powerless dust suppression technology, Hebei Jiaruisi Environmental Protection Equipment Co., Ltd. revolutionizes traditional energy-dependent dust removal systems. Specializing in controlling material-induced dust diffusion during processing, unloading, and transportation, we deliver ultra-low emission, high-reliability solutions for grain, mining, and industrial sectors through energy-efficient environmental technologies. Our product portfolio covers: Fragmentation-resistant powerless dust suppression telescopic chutes YCH Powerless Dust Suppression Hoppers Powerless dust control belt conveyor transfer stations Pulse d...

More Contact

Product

PPS (Polyphenylene Sulfide) Nee

Belonging column: ②High-Temperature Resistant Dust Filter Bags

NOMEX Metax Needle-Punched Dus

Belonging column: ②High-Temperature Resistant Dust Filter Bags

Water-Repellent, Oil-Resistant,

Belonging column: ②High-Temperature Resistant Dust Filter Bags

GL Glass Fiber Needle-Punched D

Belonging column: ②High-Temperature Resistant Dust Filter Bags

PTFE (Polytetrafluoroethylene)

Belonging column: ②High-Temperature Resistant Dust Filter Bags

Polypropylene Needle-Punched Du

Belonging column: ①Medium-Low Temperature Dust Filter Bags

Water-Repellent, Oil-Resistant,

Belonging column: ①Medium-Low Temperature Dust Filter Bags

Acrylic Needle-Punched Dust Fil

Belonging column: ①Medium-Low Temperature Dust Filter Bags

Polyester Needle-Punched Dust

Belonging column: ①Medium-Low Temperature Dust Filter Bags

SOLUTIONS

• Relying on 10+independent patented technologies • Customized solution design • Full cycle service • Assisting customers in achieving environmental standards and cost optimization

Large-Flow, High-Drop Material Discharge Solutions

High Vertical Drop ①Vertical drop between the material discharge point and stockpile surface typically exceeds 20 meters, requiring multi-stage velocity reduction to minimize particle breakage.

read morePowerless Dust Suppression Discharge Solution

Credibly utcost efective an expertise and web enabled proces that improvements Completely seamless channels

read moreBelt Conveyor Transfer Point Dust Control Solution

At transfer points of potash fertilizer belt conveyors (e.g., deflector hoods, loading chutes, discharge pipes) in Qinghai Salt Lake Company, dust dispersion issues are notably severe, specifically

read moreDust Control Solutions for Wood Processing

Severe Dust Pollution Dust concentration in workshops reaches 250 mg/m³, posing significant health risks to workers. 1.2 Accelerated Equipment Wear Coarse dust particles infiltrate motors and transmission systems, increasing equipment failure rates by 30% and annual maintenance costs

read moreWear-Resistant Polyurethane Solutions for Material Conveying Lines

3.1 Extended Lifespan & Cost Savings Lifespan increased to 2 years with a 65% reduction in maintenance costs. 3.2 Noise Reduction Operational noise reduced to 80 dB, improving workplace safety and comfort. 3.3 Enhanced Screening Efficiency Screening efficiency improved by 20%;Particle breakage rate reduced to 3%, minimizing material loss.

read moreSolution for Reducing Grain Breakage in Silo Feeding

Pain Points High Breakage Rate: Existing PE liner plates in the grain silo chutes at a port result in >1.5% breakage rate for wheat and corn during loading. Residue Accumulation: Seams in the liners trap mold-contaminated grains and dust, increasing cleaning costs and posing food safety risks.

read moreBLOG

Choose Jiaruisi and build a clean and low-carbon future together!

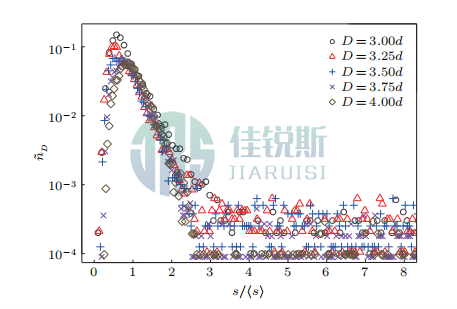

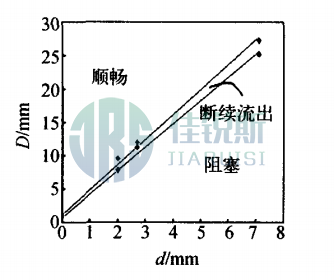

Numerical Experimental Study on

Introduction Granular materials constitute complex systems formed by numerous discrete particles inte...

查看详情Study on Granular Flow Rate and

Abstract: Sand clock experiments in three-dimensional funnels were conducted to investigate changes i...

查看详情

Chinese

Chinese